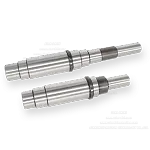

In the sophisticated powertrain systems of the automotive industry, the Shaft, though seemingly unobtrusive, is like the “backbone” of the vehicle’s power – generating heart, playing a critically important role.

Meticulous Material Selection for Toughness and Durability

Automotive operating conditions are complex, and the Shaft has to endure significant challenges. We meticulously select high – strength alloy steel as the raw material. This steel, through special heat – treatment processes, possesses extremely high strength and toughness. During the frequent starting, stopping, accelerating, and decelerating of a vehicle, the Shaft can effectively withstand alternating stresses and is less prone to fatigue fracture. Meanwhile, its excellent wear – resistance minimizes the wear between the Shaft and its mating components during long – term high – speed operation, extending its service life and ensuring the stability and durability of power transmission in the vehicle.

Precision Machining for Perfect Fit

The automotive powertrain system has extremely high requirements for the precision of the Shaft. We utilize advanced CNC machine tools and precision machining techniques to strictly control the dimensions, shape, and surface roughness of the Shaft. The dimensional tolerances of critical parts such as the journal and shaft shoulder are kept to a minimum, ensuring a precise fit with components like bearings and gears. High – precision machining makes the run – out and vibration of the Shaft during rotation negligible, effectively reducing operating noise and enhancing the smooth operation of the automotive powertrain system, thus creating a quiet and comfortable environment for drivers and passengers.

Optimized Design for Enhanced Power Transmission

We have carried out targeted design optimizations for the Shaft. The rational distribution of shaft diameters and structural layout effectively balance the strength and weight of the Shaft. While ensuring its load – bearing capacity, it reduces the Shaft’s own moment of inertia, making the powertrain system more responsive and power transmission more efficient. The unique design of connecting structures such as keyways and splines enhances the torque – transmitting ability between the Shaft and transmission components, reducing power losses and providing a powerful and stable power output for the vehicle.

Professional Service for Customized Solutions

We are well aware that different automotive brands and models have varying requirements for the Shaft. Therefore, we not only offer standard – specification products but also provide professional customization services. We communicate in depth with customers and, based on their specific power requirements, installation space, and performance indicators, tailor exclusive Shaft product solutions for them.

The automotive Shafts produced by our company, with their meticulous material selection, precision machining, optimized design, and professional service, have become core supporting components of automotive powertrain systems. In the future, we will continue to innovate and strive forward, constantly improving product quality and technological levels to contribute more to the development of the automotive industry.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]