In the complex and sophisticated operating system of automotive electrical systems, the Carbon Brush, though seemingly small, undertakes an indispensable mission and is a key component to ensure the stable operation of automotive electrical equipment.

Precise Conduction for Stable Power Supply

In key automotive electrical devices such as starters and generators, the Carbon Brush is the core hub for current conduction. Our Carbon Brushes are made of high – purity carbon materials with the addition of high – quality auxiliary components. Through special processing techniques, they possess excellent electrical conductivity. During vehicle starting, driving, and in various operating conditions, they can accurately and stably transmit electrical energy to the required parts, ensuring smooth current transfer and significantly reducing energy losses. Whether it’s meeting the high – current demand during vehicle starting or maintaining the continuous and stable power supply of the generator, they can efficiently complete the task, laying a solid foundation for the stable operation of the automotive electrical system.

Quality Material Selection for Durability

The operating conditions of automobiles are complex and variable, placing extremely high demands on the durability of Carbon Brushes. We carefully select high – quality raw materials such as graphite, electrographite, and metal (including copper and silver) graphite. These materials not only have excellent electrical conductivity but also outstanding wear – resistance and high – temperature resistance. During frequent vehicle starting and stopping, as well as long – term high – speed driving, the Carbon Brush can effectively resist wear and reduce the losses caused by friction. Even in the harsh environments of high temperature and high vibration in the engine compartment, it can maintain stable performance, significantly extending its service life, reducing the maintenance cost and replacement frequency of the automotive electrical system, and enhancing the overall reliability of the vehicle.

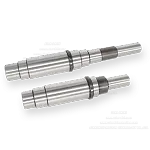

Precision Manufacturing for Multiple Adaptations

With a wide variety of automotive brands and models, each having different electrical systems, the requirements for the adaptability of Carbon Brushes are extremely strict. We rely on advanced production equipment and precision manufacturing processes to strictly control the size and shape of Carbon Brushes. From raw material mixing, pressing, sintering to processing and forming, every step follows high – standard procedures. The produced Carbon Brushes have accurate dimensions and regular shapes, which can perfectly fit the commutators or slip rings of various automotive motors. At the same time, we offer a wide range of specifications and models to fully meet the diverse application scenarios in the automotive industry.

The Carbon Brushes produced by our company for the automotive industry, with their remarkable advantages such as precise conduction, quality material selection, precision manufacturing, and professional service, have become a solid guarantee for the stable operation of automotive electrical systems. In the future, we will continue to innovate and strive forward, constantly improving product and service quality, and contributing more to the development of the automotive industry.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]