In the precise and complex internal structure of automotive electric motors, every component plays an indispensable role. The Magnet Spring, though seemingly insignificant, is a key element ensuring the efficient operation of automotive electric motors.

Precise Design for Perfect Adaptation to Automotive Conditions

Automotive electric motors have extremely strict requirements for the adaptability of components. During the design phase of our Magnet Spring, we fully consider the special operating conditions of the motor during vehicle operation, such as frequent starting and stopping, vibrations, and jolts. Its unique shape and dimensions are carefully planned and optimized multiple times to precisely fit the installation position of the magnet in the automotive electric motor, ensuring a perfect integration with the overall structure of the motor. This precise adaptation effectively prevents the magnet from shifting due to vibrations during vehicle driving, thus ensuring the stability of the magnetic field distribution in the motor and laying a solid foundation for the stable operation of the automotive electric motor under various complex conditions.

High – quality Material Selection to Withstand Harsh Automotive Environments

The operating environment of automobiles is complex and variable, placing extremely high demands on the material properties of components. We use high – strength, high – elasticity, and corrosion – resistant premium metal materials to manufacture the Magnet Spring. Through special processing techniques, the spring not only has excellent elasticity and fatigue – resistance but can also effectively resist corrosion factors such as high temperature, humidity in the engine compartment, and road salt spray. During long – term use, even under the severe challenges brought by the complex operating conditions of the vehicle, the Magnet Spring can maintain stable elastic deformation, always providing appropriate and stable fastening force for the magnet, preventing the magnet from loosening or shifting, and ensuring the stability and consistency of the magnetic field in the motor.

Reliable Fixing to Ensure Automotive Power Transmission

During vehicle driving, the stability of the magnetic field in the electric motor is directly related to the efficiency and stability of power transmission. Our Magnet Spring, with just the right elastic force, can firmly fix the magnets on both sides, ensuring that the magnets maintain the correct position and angle during the high – speed operation and frequent starting and stopping of the automotive electric motor. The stable position of the magnet ensures a uniform distribution of the magnetic field in the motor, enabling the motor to efficiently convert electrical energy into mechanical energy, reducing energy losses, and thus providing a stable and powerful power output for the vehicle, enhancing the vehicle’s power performance and driving stability.

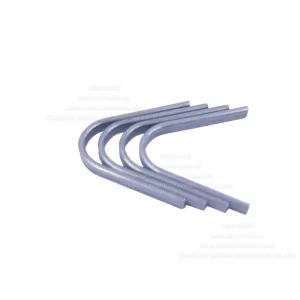

Professional Customization to Meet Diverse Automotive Needs

The automotive industry encompasses a variety of vehicle models and powertrains, resulting in diverse requirements for Magnet Springs. We not only offer standard – specification Magnet Spring products but also provide professional customization according to the specific needs of different automotive brands and models. Whether it is a Magnet Spring suitable for the high – speed electric motors of new energy vehicles or a product that meets the requirements of starters in traditional fuel – powered vehicles, we can, with our professional technology and rich experience, provide customers with the most suitable solutions. With stable and reliable quality and excellent performance, our Magnet Springs have won the trust of many customers in the automotive industry and have become a preferred component in the field of automotive electric motor manufacturing.

The Magnet Springs produced by our company, with their advantages of precise design, high – quality material selection, reliable fixing, and professional customization, provide strong support for the stable operation of automotive electric motors. In the future, we will continue to innovate, constantly improve product quality and service levels, provide automotive industry customers with higher – quality and more suitable Magnet Spring products, and help the automotive industry reach new heights.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]