In the precise structure system of automotive electric motors, the Motor Housing is by no means merely an external protective component. Instead, it is a crucial element that plays a decisive role in the overall performance of automotive electric motors.

Sturdy and Durable, Resisting Driving Impacts

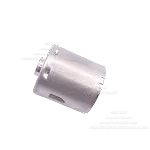

When a car is in motion, bumps and impacts are constant, which places extremely high demands on the sturdiness of the Motor Housing. Our Motor Housing is made of high – strength alloy materials and undergoes advanced forging and heat – treatment processes, giving it both ultra – high hardness and good toughness. Whether facing the severe jolts on rough mountain roads or the impacts from speed bumps on urban roads, it can provide comprehensive protection for the precision components inside the motor. Its ring – shaped structure design evenly distributes external forces, effectively reducing the risk of damage to internal motor parts caused by external collisions. This greatly extends the service life of the motor and ensures the stable and reliable operation of the automotive power system.

Efficient Heat Dissipation, Maintaining Stable Operating Conditions

Automotive electric motors generate a large amount of heat during operation, especially under conditions such as frequent starting and stopping and high – speed driving. A stable temperature is the key to ensuring the performance of the motor. The surface of our Motor Housing has undergone special treatment to optimize its heat – conduction performance. Meanwhile, the strategically distributed heat – dissipation holes on the ring – shaped edge increase the heat – dissipation area, accelerating air convection and heat exchange. This can quickly dissipate the internal heat of the motor, preventing the motor from experiencing performance degradation and frequent malfunctions due to overheating, and ensuring that the automotive electric motor can operate stably under various complex conditions.

Precision Manufacturing, Ensuring Perfect Fit

Automotive electric motors have extremely strict requirements for the compatibility of components. We use advanced CNC machining equipment and precision manufacturing techniques to strictly control dimensional accuracy. The central circular hole and the surrounding structure of this Motor Housing are precisely designed and processed in terms of size and position, enabling it to fit accurately with the motor shaft and other key components of the automotive electric motor. This high – precision fit can not only reduce vibrations and noise caused by improper assembly clearances during motor operation, enhancing the driving experience, but also optimize the internal magnetic field distribution of the motor, improving the conversion efficiency of electrical energy into mechanical energy, and providing a more powerful and stable power output for the vehicle.

Multiple Protections, Adapting to Harsh Environments

The operating environment of automobiles is complex and variable, and the Motor Housing needs to be capable of withstanding various harsh conditions. The surface of our Motor Housing has been specially treated for anti – corrosion, anti – rust, and anti – aging, which can effectively resist the erosion of corrosive substances such as rainwater, moisture, and salt. Even in coastal areas or on roads where salt is used for de – icing in winter, it can maintain good performance. The ring – shaped structure tightly wraps the interior of the motor, and its excellent sealing performance can effectively prevent dust, sediment, and other impurities from entering the motor, protecting internal windings, electronic components, etc. from contamination and damage, and creating a safe and stable operating environment for the automotive electric motor.

Flexible Design, Meeting Diverse Needs

The automotive industry encompasses a variety of vehicle models and power systems, and different customers have significantly different requirements for the Motor Housing. This Motor Housing of ours features a highly flexible design, and the central circular hole and the surrounding structure can be customized and adjusted according to specific customer needs. Whether it is to meet the special size requirements of high – speed electric motors in new energy vehicles, the installation needs of starter motors in traditional fuel – powered vehicles, or to add special functions for motors in special – purpose vehicles, our professional technical team can, with rich experience and innovative capabilities, provide customized solutions to meet the diverse application requirements of the automotive industry.

The automotive Motor Housing produced by our company, with its excellent quality, outstanding performance, and attentive service, has become a trusted choice in the automotive industry. In the future, we will continue to innovate, constantly improve product quality and technical levels, provide automotive industry customers with higher – quality Motor Housing products, and help the automotive industry reach new heights.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]