In today’s rapidly – developing automotive industry, the power system of a vehicle is like its heart, and the Rotor Assembly is an indispensable and crucial component within this heart.

Ingenious Structure, Shouldering the Mission of Power Transmission

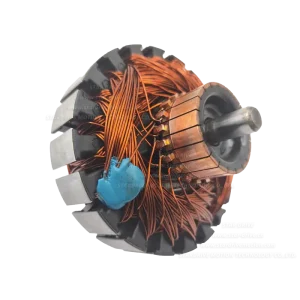

The automotive Rotor Assembly is mainly composed of key parts such as the iron core, winding, commutator, and shaft. The iron core is made by laminating high – permeability premium silicon steel sheets. This structural design effectively reduces hysteresis and eddy – current losses, enabling efficient conduction and concentration of the magnetic field, thus laying a solid foundation for the energy conversion of the motor. The winding is tightly wound around the iron core. When current passes through it, a powerful electromagnetic force is generated to drive the rotor to rotate. The commutator is connected to the winding. Through cooperation with the brushes, it accurately changes the direction of the current, ensuring that the rotor can rotate continuously and stably, thereby efficiently converting electrical energy into mechanical energy and providing strong power for the vehicle’s movement. The shaft is the supporting and power – output component of the entire Rotor Assembly. It has high strength and precision and can stably transmit torque to drive the vehicle’s transmission system.

High – quality Material Selection, Laying the Foundation for Excellent Performance

The quality of materials directly determines the performance and reliability of the Rotor Assembly. We carefully select high – quality raw materials and strictly control every production process. The silicon steel sheets used for the iron core have the characteristics of low iron loss and high magnetic flux density. While ensuring efficient magnetic – field conduction, they can effectively reduce energy losses and improve the efficiency of the motor. The winding uses high – purity copper wires. Their good electrical conductivity and flexibility ensure smooth current transmission, reduce resistance heating, and enhance the stability and durability of the Rotor Assembly. The commutator is made of materials with excellent wear – resistance and electrical conductivity, which can maintain good contact performance during frequent current commutation, reduce wear, and extend the service life. The shaft is made of high – strength alloy steel. Through special processing and heat – treatment processes, it has excellent strength, toughness, and fatigue – resistance, and can withstand various stresses under high – speed rotation and complex operating conditions, ensuring stable and reliable power transmission.

Precision Manufacturing, Ensuring Efficient and Stable Operation

The precision of the manufacturing process is an important criterion for measuring the quality of the Rotor Assembly. We use advanced automated production equipment and high – precision processing techniques to strictly control the entire production process of the Rotor Assembly. From the punching and laminating of silicon steel sheets, to the winding and welding of the winding, and then to the processing and assembly of the commutator and shaft, every step follows strict process standards and quality – control systems. By precisely controlling dimensional accuracy, geometric tolerances, and assembly clearances, we ensure that all components of the Rotor Assembly fit closely and operate smoothly. The produced Rotor Assembly features low vibration, low noise, and high efficiency, and can operate stably under various operating conditions of the vehicle, providing continuous and reliable power output for the vehicle.

Professional Service, Helping Customers with Peace of Mind

As a partner in the automotive industry, we not only provide high – quality Rotor Assembly products but also are committed to offering professional and considerate services.

The automotive Rotor Assembly produced by our company, with its ingenious structure, high – quality material selection, precision manufacturing, and professional service, has become a reliable guarantee for the stable operation of the automotive power system. In the future, we will continue to innovate, constantly improve product quality and service levels, contribute more to the development of the automotive industry, and help vehicles reach higher levels in terms of power performance and reliability.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]