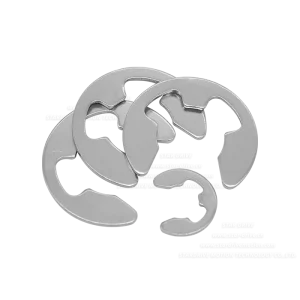

In the complex and precise mechanical system of an automobile, every component is of great importance. Although Snap Ring & Washer seems insignificant, it plays an indispensable role in ensuring the stable operation of various automotive components.

Ingenious Design for Secure Connection

Our Snap Ring & Washer is designed with full consideration of the special requirements of automotive operation. Its unique ring – shaped structure and open – end design enable it to be easily installed on shafts or holes. Through its own elastic deformation, it generates a clamping force to firmly fix the components it cooperates with, effectively preventing loosening and displacement. Whether in key power components such as automotive engines and transmissions, or in safety – related components such as the suspension system and braking system, the Snap Ring & Washer can, with its precise design, ensure a stable connection between various components, laying a foundation for the reliable operation of the vehicle.

High – quality Material Selection for Superior Quality

The quality of materials directly determines the performance and service life of Snap Ring & Washer. We carefully select high – strength and high – elasticity premium metal materials, such as spring steel, as raw materials for manufacturing Snap Ring & Washer. These materials have passed strict quality inspections and possess excellent fatigue resistance and corrosion resistance. During the operation of an automobile, the Snap Ring & Washer needs to withstand frequent vibrations, impacts, and various complex stresses. The materials we choose can maintain stable elasticity and strength under such harsh conditions, and are not prone to deformation or breakage, ensuring the long – term effectiveness of its fastening function and providing long – lasting and reliable protection for automotive components.

Precision Manufacturing for Reliable Performance

The precision of the manufacturing process is a key factor in measuring the quality of Snap Ring & Washer. We adopt advanced automated production equipment and high – precision processing techniques to strictly control the production of Snap Ring & Washer. From the cutting and forming of raw materials to surface treatment and quality inspection, every step follows strict standards and specifications. We precisely control parameters such as the dimensional accuracy, open – end size, and elastic coefficient of the Snap Ring & Washer to ensure that each product meets high – quality requirements. The produced Snap Ring & Washer features accurate dimensions, uniform elasticity, and a smooth surface, enabling it to perfectly cooperate with automotive components and stably perform its fastening function.

Professional Services for Customer Development

We are well aware that high – quality products need to be accompanied by attentive services. We can, with our in – depth understanding and rich experience in the automotive industry, provide customers with professional technical consultations and accurate product recommendations, helping them select Snap Ring & Washer products that best suit their production needs. The automotive Snap Ring & Washer produced by our company, with its advantages of ingenious design, high – quality material selection, precision manufacturing, and professional services, has become a reliable guardian for the stable connection of automotive components. In the future, we will continue to innovate, constantly improve product quality and service levels, provide higher – quality Snap Ring & Washer products for the automotive industry, and help the automotive industry reach new heights.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]