In the continuous pursuit of innovation and excellence in the automotive industry, Plastic Parts have become an indispensable key element in automotive manufacturing due to their diverse functions and advantages. Our company, with a deep – rooted presence in the automotive field, is committed to providing customers with a wide variety of automotive Plastic Parts of superior quality, fully meeting the diverse needs of automotive production.

Diverse Designs for Varied Requirements

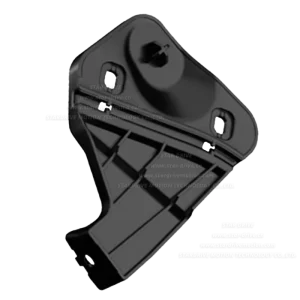

Different parts and systems of a vehicle have distinct functional and design requirements for Plastic Parts. Our automotive Plastic Parts cover all areas from interior to exterior, and from the engine compartment to the chassis, with each product carefully designed. In terms of interior components, whether it’s the exquisite dashboard housing, comfortable seat components, or convenient center console trim, we focus on the integration of ergonomics and aesthetics. These not only provide a comfortable tactile and visual experience for drivers and passengers but also optimize the interior space layout and operational convenience through rational structural design. Exterior Plastic Parts such as bumpers and spoilers, while meeting the demand for improved aerodynamic performance, also take into account aesthetic appeal and personalization, creating a unique appearance for the vehicle. Plastic Parts applied in the engine compartment and chassis, such as engine guards and wire harness protectors, emphasize functional design, providing reliable protection for key components and ensuring the stable operation of the vehicle under complex conditions.

Careful Material Selection for Outstanding Quality

The quality of materials directly determines the performance of Plastic Parts. We adhere to strict material – selection criteria and carefully choose the most suitable high – performance plastic materials according to different types of Plastic Parts and usage scenarios. For components subject to high mechanical stress, high – strength engineering plastics are selected. Their excellent rigidity and toughness can effectively withstand external impacts while ensuring the structural stability of the components. For Plastic Parts used in high – temperature environments, materials with excellent heat – resistant properties are adopted to ensure stable physical and chemical properties in high – temperature areas such as the engine compartment, without deformation or aging. At the same time, we attach great importance to the weather resistance, chemical corrosion resistance, and environmental friendliness of materials, enabling Plastic Parts to not only adapt to various harsh climatic conditions and chemical erosion but also meet the strict environmental requirements of the current automotive industry, contributing to the sustainable development of automobiles.

Precision Manufacturing for Stability and Reliability

Advanced manufacturing processes are a solid guarantee of our product quality. We are equipped with industry – leading injection – molding equipment, high – precision mold – processing centers, and automated production lines to achieve precision manufacturing from raw materials to finished products. During the injection – molding process, by precisely controlling key parameters such as temperature, pressure, and injection speed, we ensure the dimensional accuracy, surface quality, and internal structural uniformity of Plastic Parts. The application of high – precision molds perfectly presents product details, effectively reducing defects such as burrs and flash, and improving the appearance quality and assembly accuracy of products. A strict quality – inspection system runs through the entire production process, from the incoming inspection of raw materials, to in – process online monitoring, and then to comprehensive performance testing of finished products. Every step is rigorously controlled to ensure that each Plastic Part delivered to customers has stable and reliable quality.

Professional Services for Joint Progress with Customers

We are well aware that high – quality products require attentive services. We can provide customers with comprehensive and full – cycle professional support. We deeply understand customer needs and, with our rich industry experience and professional knowledge, offer accurate product – selection advice and customized solutions.

The various automotive Plastic Parts provided by our company, with their diverse designs, high – quality material selection, precision manufacturing, and professional services, have become a trusted partner in the field of automotive manufacturing. In the future, we will continue to innovate, constantly improve product and service levels, bring more high – quality and efficient Plastic Parts products to the automotive industry, and help the automotive industry move steadily forward on the path of innovation.

Company Profile

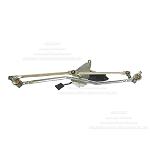

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]