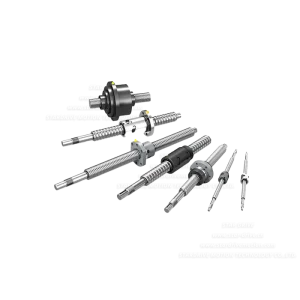

In the precisely operating system of the automotive industry Gear & Lead Screws are humble yet vital. As the rudder of power transmission in vehicles they ensure efficient and stable delivery of power to the drive wheels they act as the commander of precise control enabling steering responses that are sensitive and accurate and they serve as the creator of interior functions enabling smooth adjustment of components such as seats and windows.

Innovative Design Crafting Exceptional Performance

Our Gear & Lead Screws integrate cutting-edge design concepts and advanced manufacturing technologies. Every detail from the precision tooth profile design to the screw thread structure has undergone repeated scrutiny and optimization. Using advanced computer-aided design (CAD) and finite element analysis (FEA) technologies we ensure that Gear & Lead Screws achieve efficient smooth and low-noise operation during power transmission. The unique tooth profile design effectively reduces friction during gear meshing improves transmission efficiency and enhances the load-bearing capacity of the gears enabling them to withstand high-intensity use in complex automotive working conditions. The thread accuracy of the screw part reaches the micron level ensuring precise linear motion control capable of achieving accurate position adjustment in applications such as automotive seat adjustment window lifting and suspension system fine-tuning.

High-Quality Materials Ensuring Reliable Quality

Quality is the foundation of our Gear & Lead Screws. In material selection we strictly screen high-quality alloy steel high-strength stainless steel and other raw materials. These materials possess excellent strength wear resistance and fatigue resistance capable of withstanding frequent impacts and vibrations during vehicle operation. Through advanced heat treatment processes the internal structure of the materials is optimized further enhancing the balance of hardness and toughness to ensure that Gear & Lead Screws are not prone to wear deformation or breakage during long-term use. Additionally we conduct rigorous quality inspections on raw materials to control product quality from the source laying a solid foundation for the reliable operation of each Gear & Lead Screw.

Diverse Applications Adaptable to Various Needs

Automotive Gear & Lead Screws play critical roles in multiple key vehicle systems. In the steering system they accurately convert the driver’s operations into wheel steering motions providing sensitive and stable steering assistance to enhance driving control and safety. In the seat adjustment system they enable precise multi-dimensional adjustments forward/backward height backrest angle etc. for seats creating comfortable seating positions for drivers and passengers. In the window lifting mechanism they ensure smooth and stable window lifting facilitating adjustments to the interior environment while maintaining minimal noise. Our Gear & Lead Screw products offer broad adaptability capable of meeting the diverse needs of different vehicle models and systems from compact cars and luxury SUVs to large commercial vehicles we provide perfectly matched solutions.

Professional Services Full-Cycle Attentive Support

We understand that high-quality products rely on a sound service system. Our company has a professional and efficient service team that provides full-lifecycle support including pre-sales technical consulting product selection in-sales order tracking and after-sales installation guidance and maintenance. We always prioritize customer needs striving to build long-term and stable partnerships and create greater value for our clients.

As a core component of automotive key systems Gear & Lead Screws continue to push performance limits through our unremitting efforts driving industry development with exceptional quality and reliable performance. Choosing our Gear & Lead Screw products means choosing a benchmark in precision manufacturing and a guarantee of reliable quality. Let us join hands to unlock a new chapter in automotive driving.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]