In the precise and complex structural system of automotive electric motors, every component is like a crucial screw. Although seemingly insignificant, it plays a decisive role in the overall performance. And the Bushing is undoubtedly an indispensable and important part.

Precise Fit for Perfect Integration

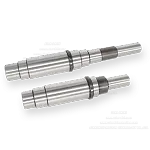

Automotive electric motors have extremely strict requirements for the adaptability of components. At the very beginning of the design and manufacturing of our Bushing, we conduct in – depth analysis of the unique structural characteristics and operating conditions of automotive electric motors. By using cutting – edge high – precision processing techniques, we control the dimensional accuracy to the utmost extent, ensuring that it can seamlessly interface with the shaft and housing of the automotive electric motor. This precise fit enables the Bushing to perfectly integrate into the overall structure of the electric motor after installation, providing smooth and stable support for the high – speed rotation of the shaft. It effectively avoids vibrations and noises caused by improper fit clearances, creating a quiet and stable operating environment for the automotive electric motor and enhancing the driving experience.

High – quality Material Selection for Durability

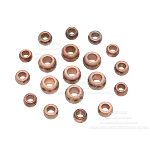

The performance of materials directly determines the quality of the Bushing. In view of the complex operating conditions that electric motors face during vehicle operation, we carefully select high – quality metal alloys or high – performance engineering plastics and other materials. These materials have excellent wear – resistance, which can effectively reduce the frictional losses with the shaft and significantly decrease the degree of wear under conditions such as frequent starting and stopping and high – speed driving of the vehicle, thus remarkably extending the service life. Meanwhile, its self – lubricating property can reduce the use of additional lubricants and lower maintenance costs. Even in harsh environments such as high temperatures and humidity, it can ensure the smooth rotation of the shaft and the stable operation of the automotive electric motor.

Efficient Load – bearing for Stable Operation

During vehicle driving, the shaft of the electric motor will bear various complex loads. Our Bushing undertakes the important mission of load – bearing. With reasonable structural design and optimization of material mechanical properties, it can effectively bear the radial and axial loads generated during the shaft’s operation and evenly distribute these loads. This prevents the shaft from deviating or deforming due to uneven stress, ensures a uniform distribution of the magnetic field inside the electric motor, makes the conversion between electrical energy and mechanical energy more efficient, reduces energy losses, and improves the stability and efficiency of the power output of the automotive electric motor, providing reliable power support for vehicle driving.

Professional Customization for Trustworthiness

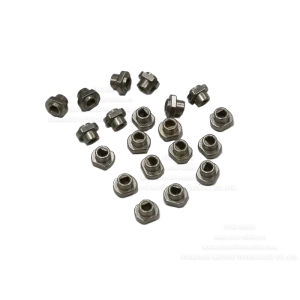

As a partner in the automotive industry, we are well aware that different automotive brands and models have diverse requirements for the Bushing of electric motors. Therefore, we not only provide widely applicable standard products but also offer professional customization according to the specific requirements of automotive manufacturers. Whether it is to adapt to the high – speed electric motors of new energy vehicles or the starters of traditional fuel – powered vehicles, our Bushing can perform tasks excellently with its reliable performance. With stable quality and a good reputation, we have won the trust of many customers in the automotive industry and become a preferred brand in the field of automotive electric motor manufacturing.

The Bushing produced by our company for the automotive industry, with its outstanding advantages such as precise fit, high – quality material selection, efficient load – bearing, and professional customization, provides solid support for the stable operation of automotive electric motors. We will continue to innovate and continuously optimize product performance to provide automotive industry customers with higher – quality and more suitable Bushing products, helping the automotive industry reach new heights.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]