In the thriving automotive industry today, the efficient operation of the power transmission and conversion system in vehicles is of utmost importance. The Commutator is a core component that acts in this crucial area.

Ingenious Structure for Key Functions

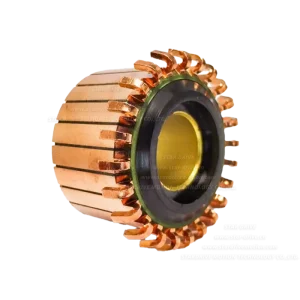

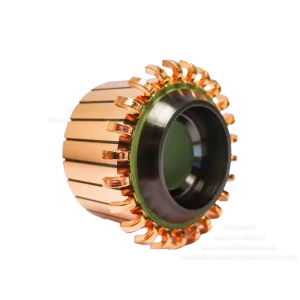

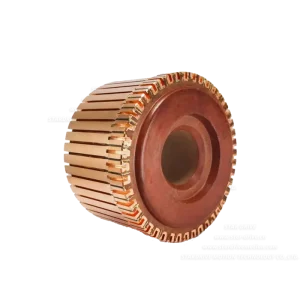

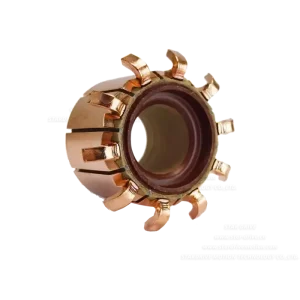

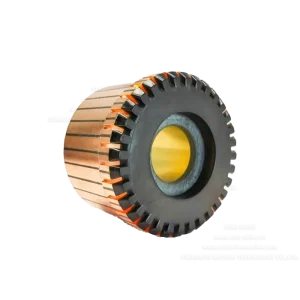

The Commutator, also known as the rectifier, is mainly composed of copper segments separated by mica sheets, with a cylindrical or disc – shaped structure. In key automotive devices such as starters and generators, the Commutator is the core of the armature component. Each copper segment is connected to multiple armature winding elements. When the armature rotates, the copper segments come into contact with the fixed brushes, achieving current commutation and thus ensuring the continuous and stable rotation of the electric motor. In automotive generators, the Commutator can convert the alternating electromotive force in the elements into direct – current electromotive force between the brushes. In motors such as starters, it can transform the applied direct current into alternating current in the elements, ensuring that the direction of the electromagnetic torque remains unchanged and providing a stable and continuous power output for the vehicle.

High – quality Material Selection for Superior Quality

We are well aware that materials are a key factor determining the performance of the Commutator. We are extremely strict in material selection. The casing is made of high – strength premium cast iron, which has excellent strength and stability, providing a solid physical protection for the Commutator and effectively withstanding external impacts and vibrations generated during vehicle operation. The gears are made of high – quality alloy steel. Through fine processing and special treatment, they have high strength and strong load – bearing capacity, enabling accurate power transmission and ensuring the smooth and stable operation of the Commutator.

Precision Manufacturing for Diverse Adaptations

With a wide variety of automotive brands and models, the electrical systems have different requirements for the specifications and performance of the Commutator. We rely on advanced production equipment and precision manufacturing processes to strictly control the entire production process of the Commutator. From raw material screening and processing, to the machining and forming of each component, and finally to assembly and debugging, every step adheres to high standards. The Commutators we produce have accurate dimensions and regular shapes, and can perfectly fit various automotive motors. At the same time, to meet the diverse needs of the automotive industry, we offer a variety of Commutator products in different specifications and models, including mechanical commutators, semi – plastic commutators, and fully – plastic commutators. Whether for traditional fuel – powered vehicles or new energy vehicles, suitable Commutator solutions can be found.

The automotive Commutators produced by our company, with their ingenious structure, high – quality material selection, precision manufacturing, and professional service, have become a reliable guarantee for the stable operation of automotive electrical systems. In the future, we will continue to innovate, constantly improve product quality and service levels, contribute more to the development of the automotive industry, and help automotive power systems reach higher performance levels.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]