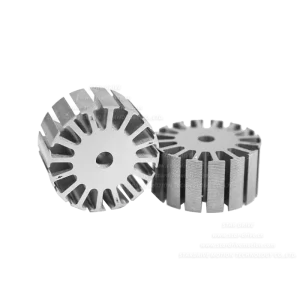

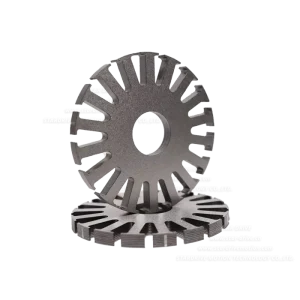

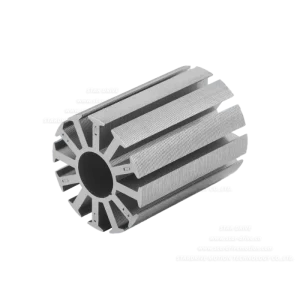

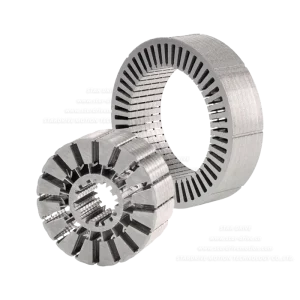

As a core component of motors, the performance of rotor lamination directly determines the operating efficiency, stability, and service life of the motor. The following details our company’s rotor lamination products from the aspects of material selection, manufacturing processes, and application scenarios:

Strict Material Selection, Laying a Solid Performance Foundation

Our rotor laminations are manufactured using high-quality electrical steel as the raw material, which offers dual advantages of high magnetic permeability and low iron loss. The high magnetic permeability effectively guides the distribution of magnetic flux lines, optimizing the internal electromagnetic environment of the motor and significantly improving electromagnetic conversion efficiency. The low iron loss characteristic greatly reduces energy loss caused by hysteresis and eddy current effects during motor operation, minimizing heat generation, enhancing motor energy efficiency, and extending equipment service life.

Precision Machining, Ensuring Assembly Accuracy

Relying on high-precision molds and advanced stamping equipment, our rigorous manufacturing processes ensure that each lamination is dimensionally precise with minimal errors. This enables the rotor to perfectly fit with other motor components, effectively avoiding vibration, noise, and other issues caused by assembly errors. As a result, the motor operates stably and reliably, with significantly improved overall performance.

Industry Recognition Achieved

With superior performance, our rotor laminations have been widely applied in the automotive industry, deeply adapting to various automotive drive motors. They provide stable and powerful power output for vehicles, earning high recognition and trust from numerous industry clients.

Company Profile

Our business started with humble automotive parts. Building on China’s robust supply chain advantages and our sincere service, we’ve steadily gained trust from global partners while continuously expanding our product range – now covering power window systems, wiper systems, washer pumps, and condenser fan systems.

Most of the time, we provide SKD or CKD to customers.

As motor for window reguator\wiper\washer pump\starter\fan\Alternator.

As rotor assembly/bearing/bushing/motor housing/magnet/carbon brush/commutato/linkage rod/bowden cable/steel wire rope/worm gear/worm wheel/shaft/gear……

In addition, we can also provide complete assembly lines for motors, production equipment for automotive control cables (excluding steel wire rope production equipment), relay assembly lines, stamping equipment, and testing equipment.

Contact Us

Website: www.stardrivemotion.com

Mail: [email protected]